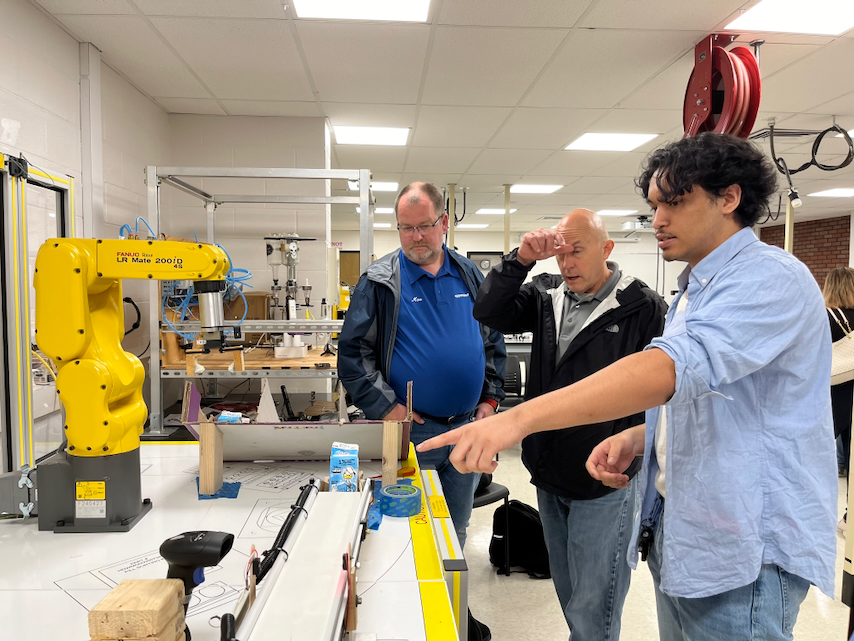

Seniors in the Electrical Engineering Technology program at Springfield Technical Community College presented projects on May 16, 2024.

This year’s Electrical Engineering Technology EET-265/L Advanced Automation Project senior students were grouped into two teams to create two separate projects for this capstone course and lab. The students research and select the ideas for their projects the first week of the Spring semester and then work on their projects for a minimum of 6 hours per week during their EET-265 Advanced Automation lab times until the presentations in mid-May.

The two projects this year were a Milk Sorting Process and a Vending Machine with Food & Beverage Options. The seven team members for the Milk Sorting Process consisted of Carter Brunelle, Alexis Gomez, Cody Guild, Chelsie Rivera, Cristopher Rivera, Daniel Stefanik and Charles Williams. The six team members for the Vending Machine Process consisted of Genesis Cabassa Cabrera, Adrian Cotto, Samuel Frechette, William Henry, Eric Leduc and Jacob Szczygiel.

What are the requirements of the project?

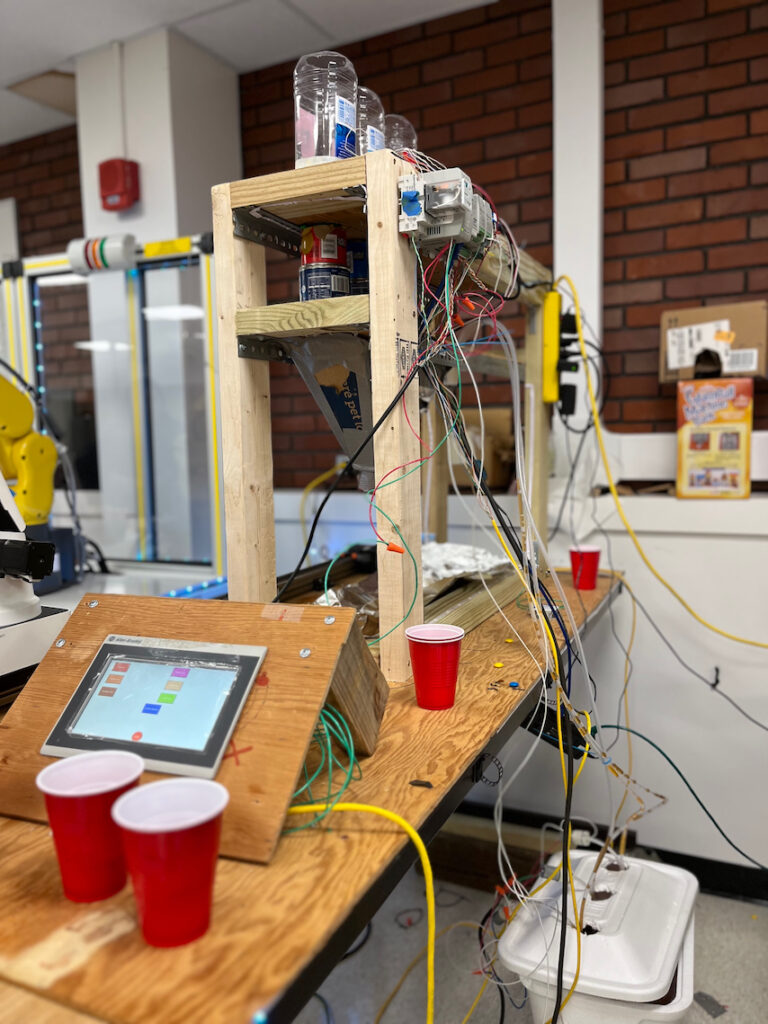

The requirements are that the process be under the control of an Allen-Bradley PLC (Programmable Logic Controller, a ruggedized computer used to control industrial processes), an HMI (Human-Machine Interface, aka “touchscreen”) and an industry-standard Fanuc robot. The teams incorporated conveyors, pneumatics, motors, various microcontrollers, 3D Printed components as well as other robots to complete their projects. Students are required to design and build the physical structures and frames for their projects demonstrating their competence with hand tools and power tools. They also have to incorporate all of the electrical wiring and programming of the various control devices so electrical troubleshooting skills are a big part of the process.

Each device programs in its own language/interface so the teams have to become proficient in no fewer than five different programming interfaces for the PLC, HMI, Fanuc Robot, Raspberry Pi/BS2 plus the 3D printer. Designing and creating the proper interfaces so these various devices can communicate with each other is always a challenge. This capstone course requires EET students to use various aspects of many of the courses in the EET Curriculum, as well as adding in some specific knowledge as required for each project.

Milk sorting process explained

The Milk Sorting Process consisted of varieties of milk moving on a conveyor belt which were then transferred to a second conveyor for barcode scanning. The UPC barcode was scanned on each product as it travelled down this second conveyor. At the end of the conveyor, a Fanuc robot would pick up the milk, and using the barcode information, the robot would sort & place it in its proper receiving bin. The entire process was under the control of the HMI and PLC with a Raspberry Pi assisting.

Vending machine process explained

The Vending Machine Process would use the HMI screen to prompt the user to input their preference for food and/or soda. Once that input was received, the project used a Fanuc robot to place a cup (or two) from a dispenser into the waiting cup holder of a Dobot Robot. Once done, the Dobot would move into position so that one cup was under the appropriate dispenser for the food item to be filled, and then move so that the second cup would be under the liquid dispensing nozzles. When this cup was filled with the desired beverage, the Dobot would then move down the translation table to present the cup(s) of desired product to the user. At the presentations, both teams were able to demonstrate their projects which proved to represent a successful culmination of their studies in the Electrical Engineering Technology Program here at STCC.