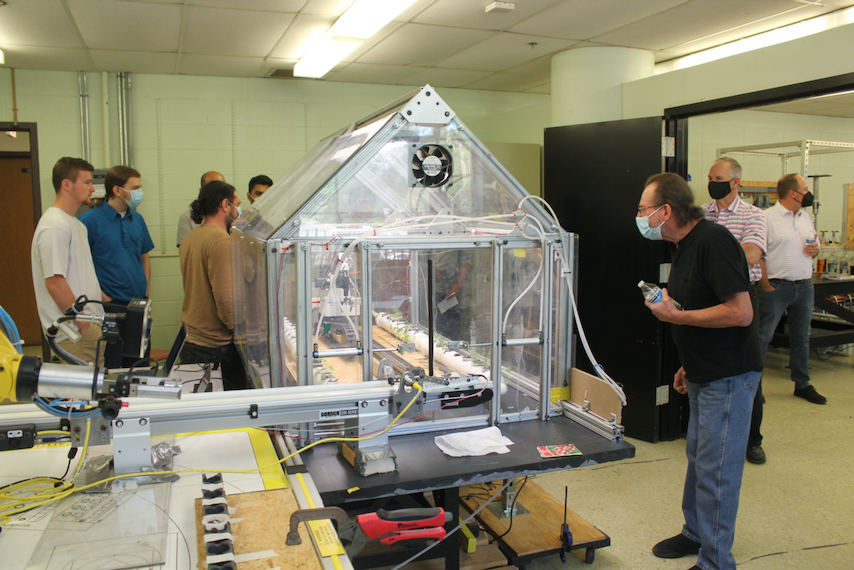

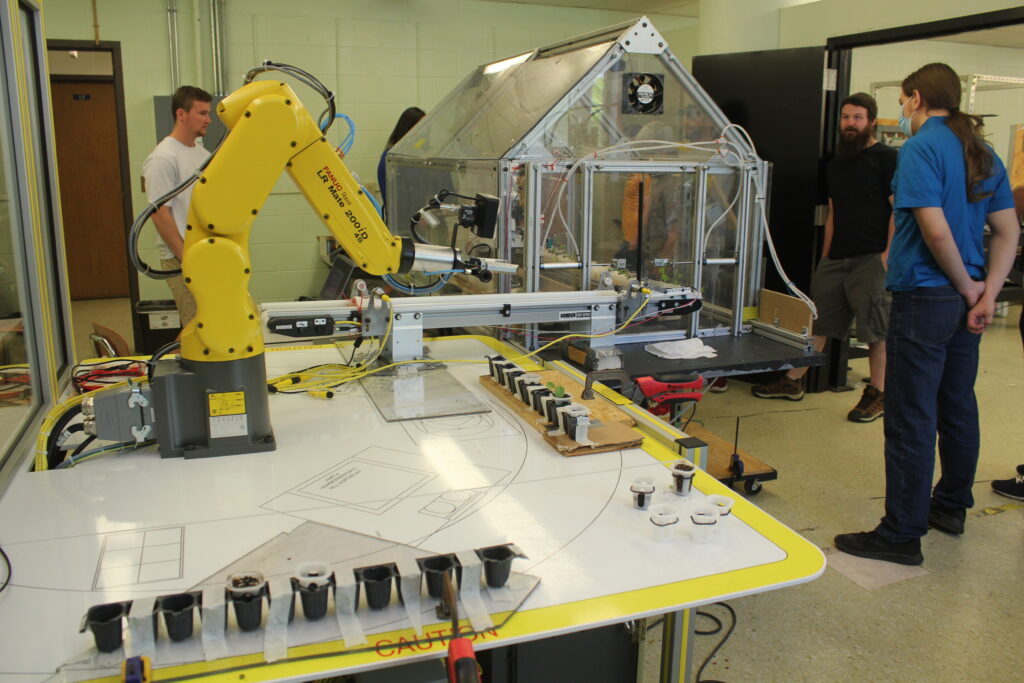

This year’s Electrical Engineering Technology Advanced Automation project is an Automated Hydroponic Greenhouse facility. The overall project is under the control of an Allen-Bradley Micro850 series PLC and PanelView HMI (Touchscreen) display and includes Fanuc LR-200 and Dobot Magician robots, as well as a conveyor and hydraulic & pneumatic components, plus a micro-controller and various sensors which are all used in the project.

“This is our capstone project. We’ve used everything we’ve learned over the past two years and incorporated it to make this happen,” one of the students said.

“We built everything you see here from the ground up – the greenhouse, the plexiglass,” said another student. “We had to make lots of modifications.”

Over the span of 15 weeks, the team of nine senior E.E.T. students conceived the idea, built the structures from scratch, designed all aspects of the project and did all of the wiring, interfacing, soldering & pneumatic connections. In addition students had extensive and diverse programming challenges with the PLC, the HMI display, the Fanuc and Dobot robots and Arduino Micro-Controller.

The project begins when the Fanuc robot picks up a small pot of nutrient rich soil from the area where the seed was inserted, to a conveyor belt where it is then moved to the door of the greenhouse. The Dobot robot picks up this seeded pot and places it into the hydroponic system at the location specified by the operator. Once inserted, it will receive all of its care by way of the automated control of the PLC.

When the plant is of sufficient size to be relocated, the process reverses itself. The operator selects the plant to be moved via the HMI display and the Dobot will pick up the plant and move it to the conveyor. The conveyor will bring it to the Fanuc robot which picks it up and places it in a shipping container.

The control and HMI display not only provide complete touch-screen operational control over the automated functions of the greenhouse, but also includes the monitoring functions of parameters such as temperature, humidity, pH and total dissolved solids. Automated pumps circulate water throughout the hydroponic system and adjust pH and add fertilizer & fresh water as needed. Lighting, temperature & humidity are also automated by the incorporation of LED grow lights and fans.

The students were under the guidance of Prof. Chuck Ruotolo and Prof. Rick Jagodowski of the E.E.T. program. The students also received encouragement and guidance for this project from STCC Prof. Tom Smith of the Landscape Design and Management Department.

The students involved in the project are (alphabetically):

*Nick DeSantis

*Jorge Gonzalez

*Korey Houle

*Joey Jagodowski

Rob Lizak

*Cole Lozinski

Abdulrahman Naser

William Penalo

Ihsan Salman

* indicates graduating in June 2022

Learn more about STCC’s advanced manufacturing programs. Interested in becoming a STCC student? Contact Admissions: admissions@stcc.edu or call (4`3) 755-3333.